TOTH MOLD/DIE INC. BLOG

Toth Mold/Die Inc. Since 1982Most Recent Posts

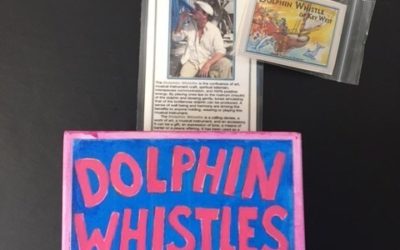

Entrepreneur Steve Allerton’s Whistling Journey

Patience is a NEEDED quality of an entrepreneur It's a trendy word these days... "Entrepreneur" -But I bet that a lot of the new "digital economy" entrepreneurs don't realize the unpredictable journey that they're about to go on. Recently, I had the pleasure of...

“7 Easy Steps” to Developing a Product for Injection Molding

Outlined below are “7 Easy Steps” that will guide you in the successful development of a product using the injection molding process. 1. Product Concept This is your idea of a product that you think has a good chance of selling. This could range from just an idea in...

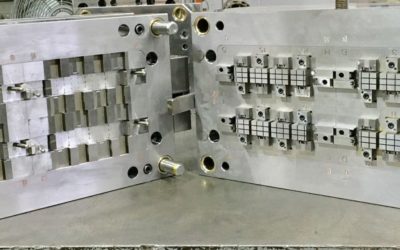

The Anatomy of an Injection Mold Used in the Injection Molding Process

Injection Molding Process An injection mold used in the injection molding process, consists of a two piece mold that is opened and closed to allow plastic to be injected under tremendous pressure when the mold is closed, to create a part. After a short...

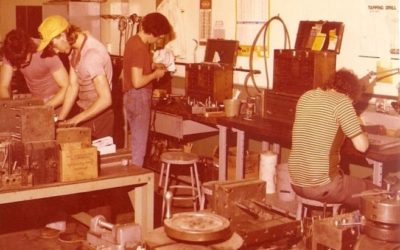

The Good Ole Days at Toth Mold/Die Inc.

Toth Mold/Die Inc. - 3 Brothers & An Old School Father! When we started out some 41 years ago it was a crazy time. Picture three brothers that did not know much at all about the injection molding/mold building trade starting to work for our very experienced...

What You Need To Know About the Injection Molding Process

In my opinion, the injection molding process is the quickest and most reliable form of producing a thermoplastic part. Cycle times can be as fast as three seconds and can produce one to 128 parts with each cycle. The repeatability of the part dimension is...

Steps for Scheduling Production Run in Injection Molding

Scheduling and running production of injection molded parts is an important operation of any molding company. Most molding companies usually have several sizes of injection molding machines which are categorized by the shot size and also the tonnage. Shot size means...

Polishing Mold Surfaces for Injection Molding

There are a variety of finishes that can be put onto an injection mold surface, from etching the surface to polishing the surface to a high sheen. For an etched surface, normally if possible, a ground finish is best to start with. However, if the cavity needs to be...

Scheduling Production for Injection Molding

Since I have been in the injection molding trade, scheduling production runs has changed drastically over the years. When I first started in the injection molding trade, scheduling production runs were very predictable. Companies would forecast what their expected...

Injection Molding a Five Inch Long Tube

One of our customers approached Toth Mold/Die Inc. with a request to produce a 5 in. long tube with a .375 in. o.d. x .265 in. i.d. using the injection molding process. The reason for injection molding this part and not extruding it was because the length of the part...

32 Years in the Injection Molding Industry

Toth Mold/Die Inc. has just celebrated our 32nd anniversary of being in the injection molding industry. It has been a quick 32 years and very eventful. A lot of things come to mind when I think back to 1982. My two brothers, my father and myself were running...