by Tim Toth | Mar 16, 2021 | Blog, Injection Molding, Inventors

Developing plastic parts using the injection molding process first begins with a concept whether it is a new product or changing/re-designing an existing one. Second will be the design stage. Once these two steps are completed, often a 3-D printed part is made to test...

by Tim Toth | Dec 1, 2020 | Blog, Injection Molding, Injection Molding Company

What is an Injection Molding One Stop Shop? An Injection Molding One Stop Shop is a company that provides all the services you need to produce a product from start to finish. There are companies out there that claim they are a One Stop Shop for injection molding but...

by Tim Toth | Oct 1, 2020 | Blog, Injection Molding

PPE – The Sudden Need for Personal Protective Equipment 2020 will go down in the record books for many things. Besides the ongoing fight to eradicate COVID-19, we’re hoping this year has opened our eyes, as Americans, to how vulnerable we are. Our free market...

by Tim Toth | Jul 16, 2020 | Blog, Injection Molding

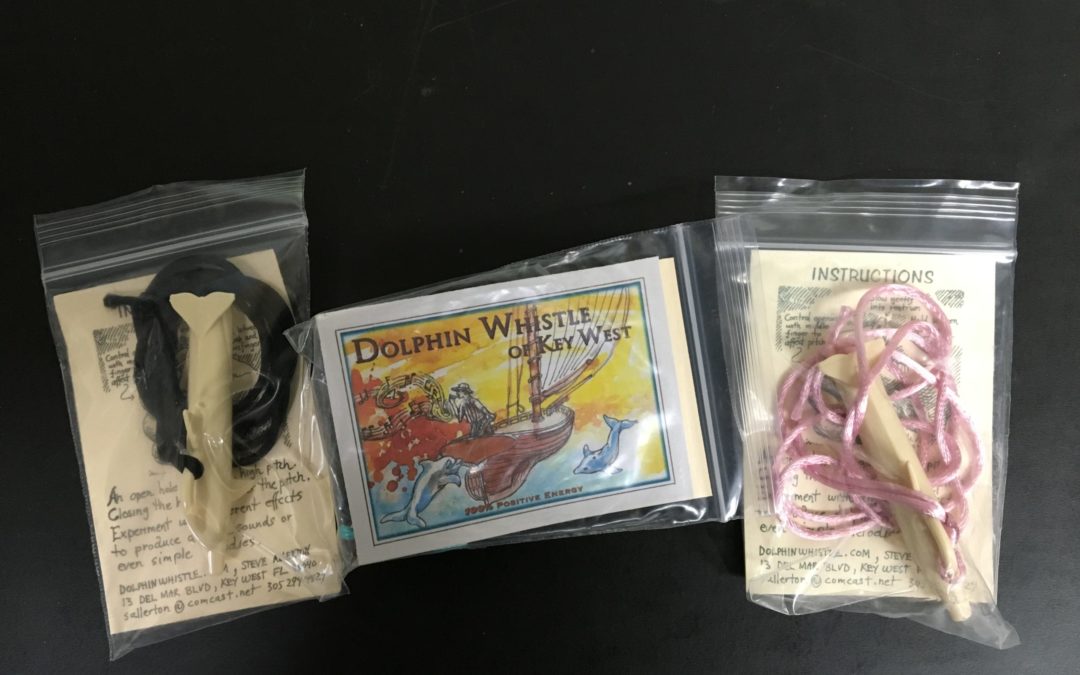

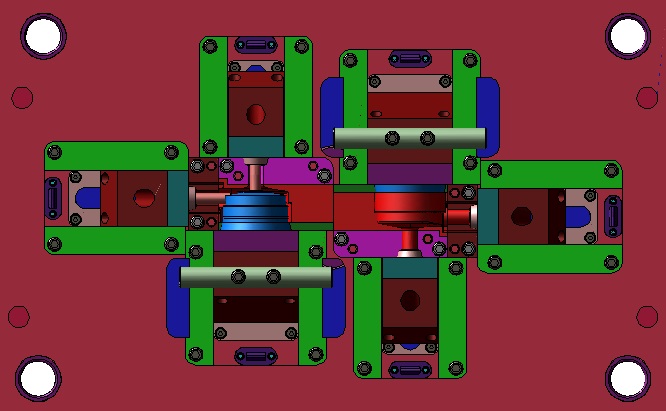

Overmolding brass, steel or plastic inserts can be very challenging. Overmolded inserts are usually held in place by shutting off on each half of the cavity or core. Most of the time, there needs to be a preload of .002/in. – .005/in. to insure there is no...

by Tim Toth | Oct 11, 2018 | Blog, Injection Molding

As a rule, an injection mold should be made for only one type of product. The main reason for this is that the different shapes may have different molding characteristics and the slower running shape will control the molding cycle and production output....

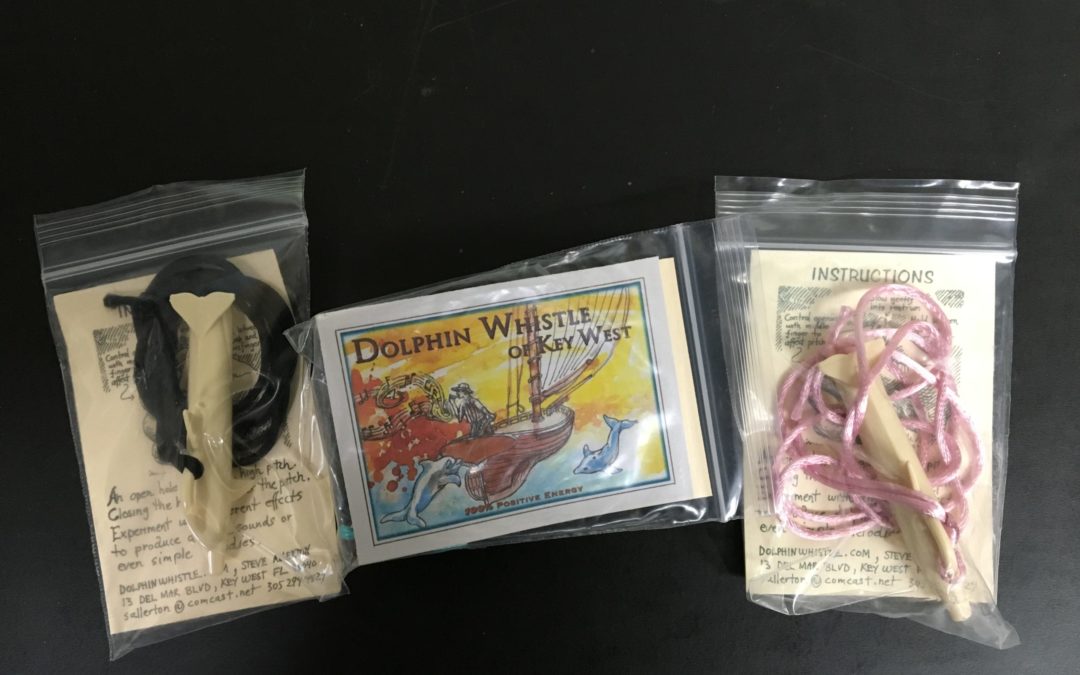

by Michael Fraser | Oct 4, 2018 | Blog, Featured Customer, Injection Molding, Inventors

This is one of those entrepreneur stories I had no idea how it was going to go. I met inventor and entrepreneur, Richard Smith for lunch to hear his story. You see Richard invented a male wellness product called the Pump-N-Gro which reduces some of the symptoms of...