INJECTION MOLDS

Toth Mold/Die Inc. Since 1982Insert Molding and Overmolding

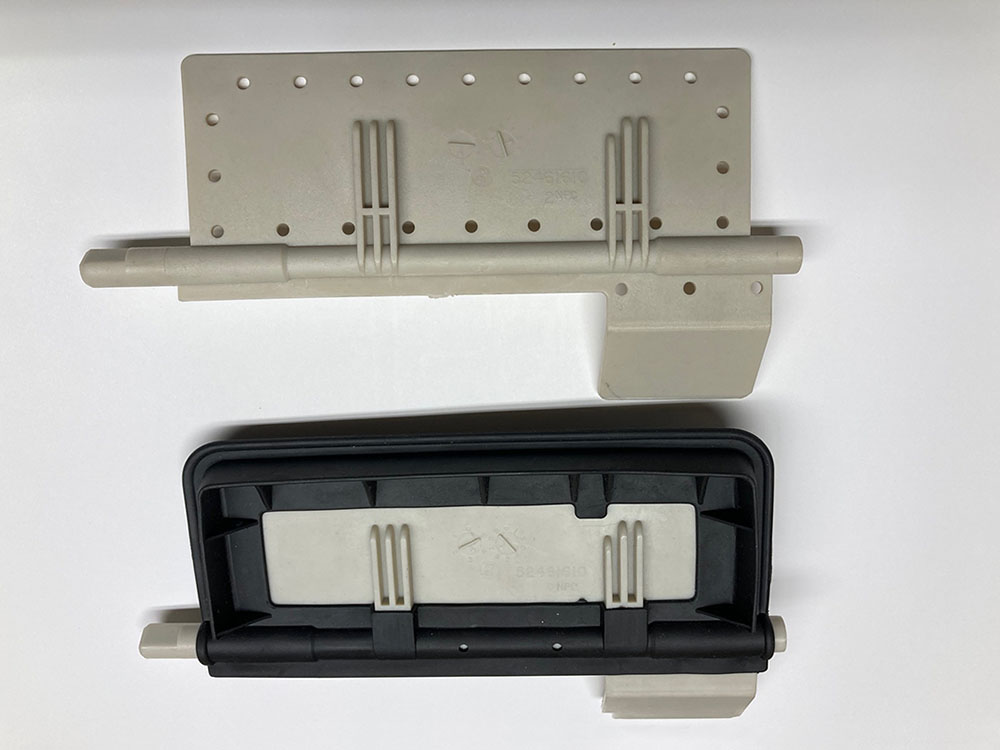

Insert molding and overmolding are basically the same type of process. An insert made from usually metal or plastic is placed in the injection mold and is held in place during the injection molding cycle while plastic is molded around it. The insert must be held in position in such a way that it will not move from the high injection pressure. Most overmolded parts have a portion of the insert exposed as this area can be used to hold the part in place. If plastic is used as the material for the insert to be overmolded, caution must be taken in the selection of the type of plastic. It must have a 50°F difference in the melt temperature so the plastic being used for molding over the insert does not melt it. Calculating the shrinkage of the part is sometimes difficult. The shrinkage will just occur where there is no insert exposed.

Insert Molding and Overmolding Your Parts

One of the most common styles of insert molding in the injection molding industry is the use of threaded inserts. Many applications using a screw in plastic will not perform so brass or some kind of metal threaded insert is used. The insert usually has a knurl on the outside diameter or some kind of flat to hold the insert from coming out of the plastic injection molded part. The threaded inserts are purchased from a company that specializes in making these types of parts at a low cost in large quantities. The tolerances on these inserts are held pretty tight; the overall height of the threaded insert is usually held within .010/in. In this case, care needs to be taken when building the injection mold to allow for the difference in the height so there is no flash allowed to enter the threads.

There are very few limitations on overmolding in the injection molding industry. There are a lot of soft materials being overmolded onto rigid plastic in products that have handles or grips such as hand drills, screwdrivers and various other products. In the injection molding industry, the use of vertical injection molding machines are the most common used for insert molding and overmolding versus the horizontal injection molding machine most often used for standard injection molding.

Toth Mold/Die Inc. has been insert molding and overmolding for 40 years and also uses the concept of insert molding for use in prototype parts to reduce the injection mold cost by eliminating the use of cam action slides.

Contact us today so we can guide you in the right direction in insert molding or overmolding your parts.