PRODUCT DEVELOPMENT

Toth Mold/Die Inc. Since 1982Product Development – “7 Easy Steps” to Develop and Produce a Finished Product

When someone has an idea for a product, it can be very confusing on how to get started with the development and production of the finished part. Once it is determined that the product will be made out of some type of plastic, then all you will need to do is follow our “7 Easy Steps” to aid you with producing a successful product. Toth Mold/Die Inc. can assist you in all “7 Easy Steps” due to our expertise within the plastics industry for 40 years.

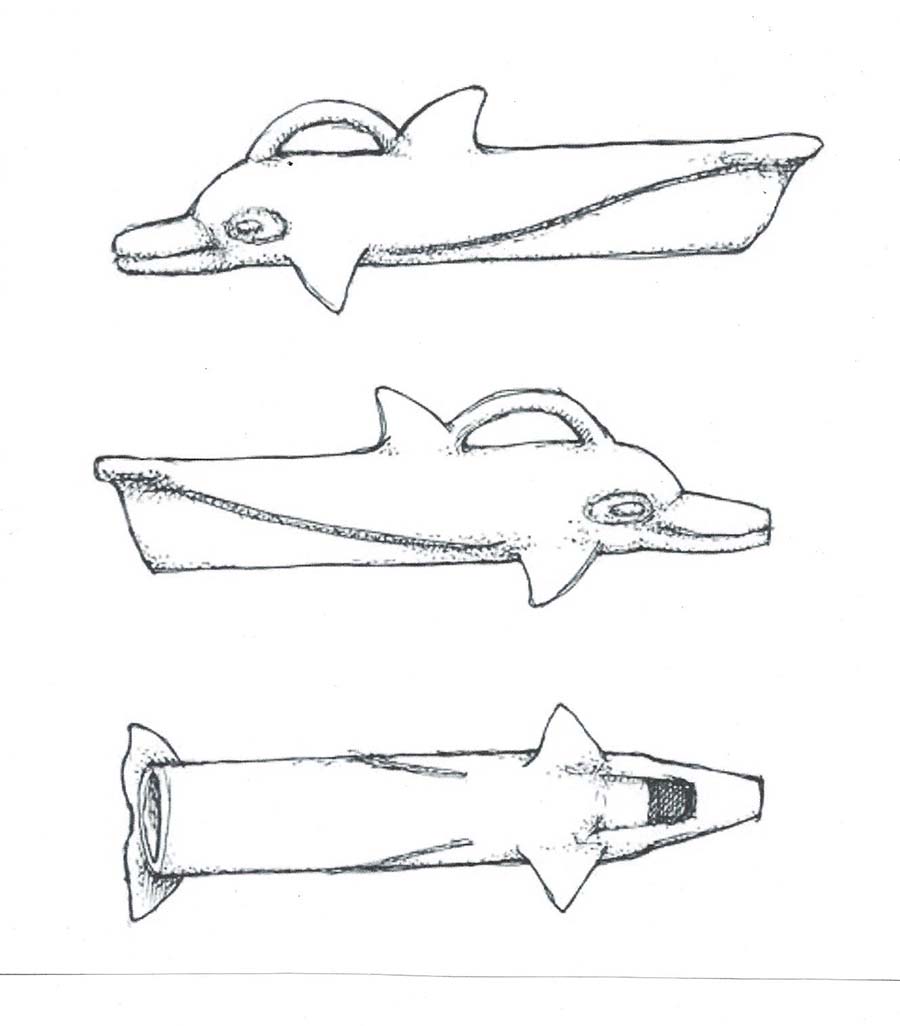

Product Development Step 1: Product Concept Provided By Customer

The product seen above is a Dolphin Whistle. Our customer only provided us with a sketch of the idea.

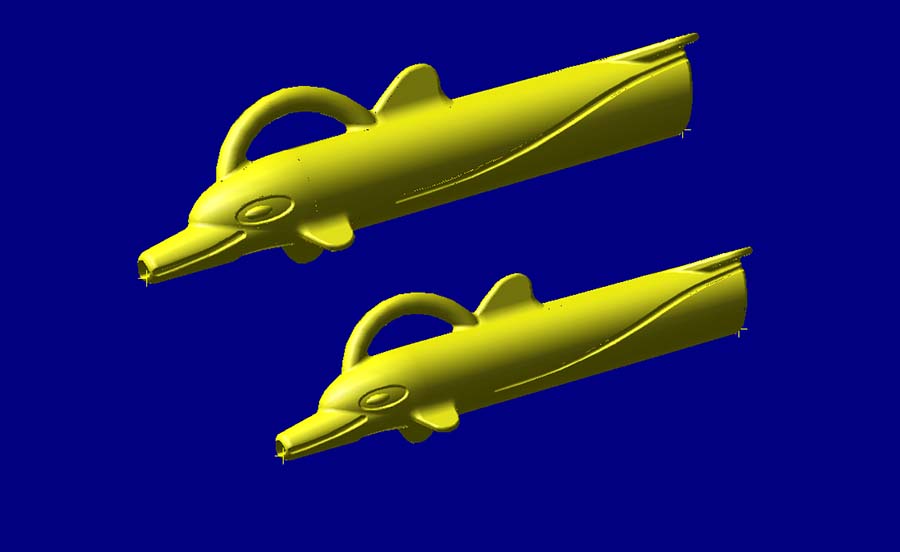

Product Development Step 2: 3-D Model, Polymer Type and Color, SLA (If needed)

- Toth Mold/Die Inc. took the sketch from Step 1 and produced a solid 3D model (see above).

- Next we chose the polymer type to resemble ivory and had the exact color matched to what our customer requested.

- In some instances, a prototype of the part is needed to visualize the function of the part.

- We can provide a prototype at a very low cost. In this case, it was not needed.

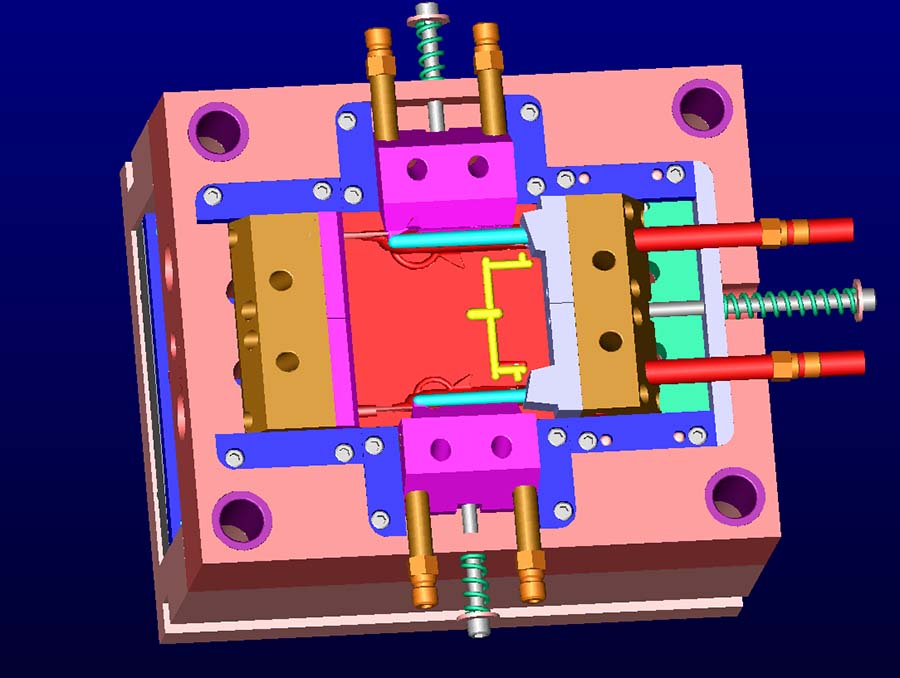

Product Development Step 3: Mold Design

Above is the 3D model of the Dolphin Whistle mold.

- This step is very important.

- Toth Mold/Die Inc. has 40 years of experience in designing molds.

- We also look at both the part and mold design together so we can keep the mold cost down.

Product Development Step 4: Mold Build

- At Toth Mold/Die Inc. we have 40 years of experience in building injection molds from prototype to high production.

- We also guarantee molds and maintain them at no charge while they are in production at Toth Mold/Die Inc.

Product Development Step 5: Sample Mold

- Once the mold is completed, it is then sampled and typically 50 – 100 parts are produced.

- The parts are then inspected for dimensions, color and function of the part.

- Any adjustments that are needed to be made as far as dimensions or mold function will be done and then sampled again.

Product Development Step 6: Production Run

- After the parts are approved, then the first production run will be done.

- During this phase the parts are checked for consistency and also the mold is inspected during this break-in period for any problems.

- In addition, the processing is tuned in during this time to improve on the cycle time in order to run the parts as fast as possible.

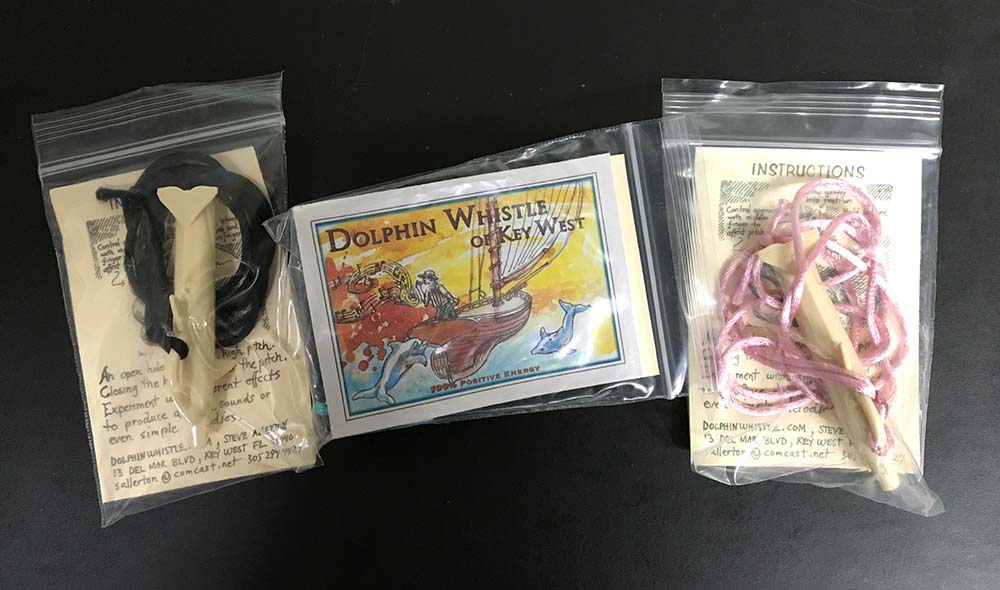

Product Development Step 7: Finished Product

- Any packaging, labeling, assembly or website marketing is done in this step.

- Toth Mold/Die Inc. can assist in all these areas.

Please check out the Dolphin Whistle Press Release and Testimonial

Parts Produced By Toth Mold/Die, Inc.

Contact Toth Mold/Die Inc. Today

Please click on the button below, we're looking forward to hearing from you!