TOTH MOLD/DIE INC. BLOG

Toth Mold/Die Inc. Since 1982Injection Molds Category

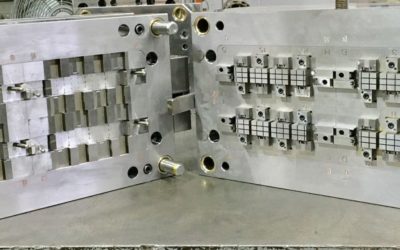

The Anatomy of an Injection Mold Used in the Injection Molding Process

Injection Molding Process An injection mold used in the injection molding process, consists of a two piece mold that is opened and closed to allow plastic to be injected under tremendous pressure when the mold is closed, to create a part. After a short...

Polishing Mold Surfaces for Injection Molding

There are a variety of finishes that can be put onto an injection mold surface, from etching the surface to polishing the surface to a high sheen. For an etched surface, normally if possible, a ground finish is best to start with. However, if the cavity needs to be...

Injection Molding Basics: What to Expect When Having an Injection Mold Built

If you have never had a part injection molded before, there are a number of important factors you will need to know before you get too far into a project. Assuming you have your part or parts designed and already have working prototypes, the next step is to get set up...

Types of Steel Used in Injection Molds for Injection Molding

There is a large selection of different types of steel used for various applications in the manufacturing of all types of products. In the injection molding industry, there are common steels used for different parts of an injection mold. One of the driving...

Types of Injection Molds Used in Injection Molding

A prototype mold is low cost injection molding tooling mainly used in order to obtain working parts. Modifications can easily be made quickly to this type of tooling. Life expectancy of this type of mold is approximately up to 1,000 parts. Some of the parts can be...

Using Cam–Action in Injection Molding

In injection molding the use of cam-action slides in injection molds is the most common and most efficient method to cast any type of undercut on a plastic part. During the initial design stage, the first thing that is looked for on a part print or a solid model is to...