Reshoring

Reshoring has been quietly making a comeback since 2010 when some of the largest brands in the industry began transitioning manufacturing back to meet their customers’ needs. Reshoring, also known as “backshoring”, is when manufacturers pull their operations out of China and other foreign countries and bring them back to North America.

The internet provides access to the world when searching for anything you want and for businesses, it’s usually linked to their bottom line – profits. There are a lot of “smoke & mirrors” behind those cheaper offshore prices. Even before the 2020 disruption, offshoring was losing its luster due to quality, regulations, and intellectual property risks. U.S. technology advancements are keeping labor costs down, while product innovation and efficiency increases. The “Made in America” claim goes far with good public image and trust, especially with U.S. consumers. 80% of American consumers prefer products made in the U.S.A. because they trust it more.

Benefits of Reshoring Your Injection Molded Products

With any project, especially with injection molded parts, having the ability to stop by the shop and talk with your moldmaker directly saves time and money. As parts are being produced, quality control and feedback in “real time” can’t be replicated overseas. When you add those two components into your production, along with shipping it back to the United States, that initial “higher price” will probably come in under your final cost from China. Reshoring also reduces the carbon footprint of long-distance transportation. We at Toth Mold/Die Inc. have always chosen to stay small allowing us the ability to be flexible for our customers’ needs.

Here is a comprehensive list of injection molding services offered by Toth Mold/Die Inc.:

- National Provider

- Product Design

- Research and Development (R&D)

- Debugs other companies molds

- Accepts injection molds from overseas to start-up production

- Consulting: Injection Molding, Injection Molds, Product Development

- Well Versed – Truly a One Stop Shop

- We do it all in-house – Do not job out and send overseas

- We are hands-on

- Manufacture/Design/Mold Building In-House

- Designs/Builds/Samples/Runs Production

Customers that have purchased injection molds from China have expressed a variety of problems:

- The final price is not what was initially expected

- Unpredictable mold lifecycles moving forward

- Is the mold really yours? Try moving your mold to another vendor

- Delivery. Easier said than done, customer has no control on time frame

- Risk of intellectual property being duplicated

- Communication barrier

- Material grade verification

2020 Disruption

This year was like no other, aside from the serious health concerns, global supply chains have been disrupted. Shipping delays and closures from suppliers have forced companies to quickly adapt and find new suppliers and partners. The plastic injection molding industry was one of the most searched categories due to the many parts and products produced deemed essential.

We’ve worked with both large and small companies, as well as inventors and start-ups. Being able to adapt or troubleshoot is what Toth Mold/Die Inc. excels at. You never know who will bring in that incredible new product to create. Inventors and start-ups have great ideas but need help with the injection molding process. Due to the initial low quantity order size, larger injection molding companies tend to turn them away. Since we’re a smaller shop and welcome custom products, we work with them. We’re happy to work through the process with them giving them the best chance for success. When we started our injection molding company nearly 40 years ago, we needed someone to give us a chance. That is why Toth Mold/Die Inc. believes in giving everyone their time to at least listen to and evaluate their product.

Reshoring Resources

- Reshoring Initiative – https://www.reshorenow.org/

- SME – https://www.sme.org/

- Reshoring Institute – https://reshoringinstitute.org/research/

- Thomas – https://www.thomasnet.com/insights/what-is-reshoring/

Toth Mold/Die Inc. Resources

We are carefully building a resourceful blog highlighting a wealth of information we’ve gained through experiences. Hopefully you will check out some of our latest posts, and if there is a topic you would like us to write about, please reach out to us at the form below.

- Benefits of Using an Injection Molding One Stop Shop

- Injection Molded Filter? They said it couldn’t be done

- Remedies of Part Shrinkage in Injection Molding

- Important Key to a Successful Injection Molding Company

- More Simple Fixes to Injection Molding Problems

- Injection Molding Challenges – Insert Overmolding

- Injection Molding for Inventors

Partnering with us can help your reshoring transition by streamlining the product design, mold building, and development. It’s always better to have a “One Stop Shop” to achieve your business goals!

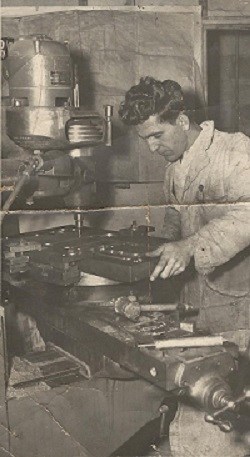

As an Injection Molding One Stop Shop for over 38 years, Toth Mold/Die Inc. offers comprehensive in-house services including part design, mold design, mold building, molding production, troubleshooting and consulting. Most importantly, the owners are 100% hands-on with all products from start to finish. If you have never used a One Stop Shop, give us a try. You will be glad you did!

Let’s start a conversation! Please fill out the form below…