TOTH MOLD/DIE INC. BLOG

Toth Mold/Die Inc. Since 1982Most Recent Posts

39th Business Anniversary Memories

I was showing molded parts to a customer from our display case and a particular project brought back many memories. This month, we proudly celebrate our 39th business anniversary. We started Toth Mold/Die Inc. in 1982 but we actually have 45 years in the injection...

Developing Plastic Parts Using the Injection Molding Process

Developing plastic parts using the injection molding process first begins with a concept whether it is a new product or changing/re-designing an existing one. Second will be the design stage. Once these two steps are completed, often a 3-D printed part is made to test...

Did 2020 Deliver the Perfect Storm for Reshoring the United States of America?

Reshoring Reshoring has been quietly making a comeback since 2010 when some of the largest brands in the industry began transitioning manufacturing back to meet their customers’ needs. Reshoring, also known as “backshoring”, is when manufacturers pull their operations...

Benefits of Using an Injection Molding One Stop Shop

What is an Injection Molding One Stop Shop? An Injection Molding One Stop Shop is a company that provides all the services you need to produce a product from start to finish. There are companies out there that claim they are a One Stop Shop for injection molding but...

Made in America has a new reality, especially for PPE – Personal Protective Equipment.

PPE - The Sudden Need for Personal Protective Equipment 2020 will go down in the record books for many things. Besides the ongoing fight to eradicate COVID-19, we’re hoping this year has opened our eyes, as Americans, to how vulnerable we are. Our free market mindset...

Remedies of Part Shrinkage in Injection Molding

One of the most common problems in injection molding is determining the shrinkage rate of a part that is going to be injection molded. Material data sheets provide a shrinkage rate for the material that is going to be used for a part. However, this rate is only a...

Important Key to a Successful Injection Molding Company

There are many key factors to operating a successful injection molding company. I want to talk about one that I think is one of the most important and that would be having a foreman that is dedicated and also knowledgeable in injection molding. The title "Foreman" in...

More Simple Fixes to Injection Molding Problems

When injection molding problems appear during a production run it is usually due to a malfunction of the injection molding machine. If parts are running fine for most of the day and then things start changing, there are a few things I look at right off the bat. If the...

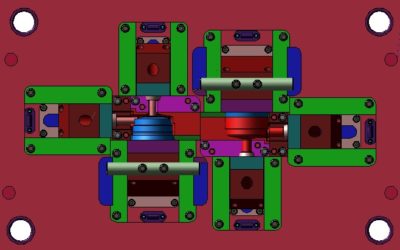

Injection Molding Challenges – Insert Overmolding

Overmolding brass, steel or plastic inserts can be very challenging. Overmolded inserts are usually held in place by shutting off on each half of the cavity or core. Most of the time, there needs to be a preload of .002/in. - .005/in. to insure there is no leakage of...

Injection Molding for Inventors

Toth Mold/Die Inc. has been successfully working with inventors for over 35 years. First off, all I would like to define what an inventor is in my eyes. An inventor is someone who has a dream of making a product that will be purchased by the public or be used by the...