by Tim Toth | Mar 16, 2021 | Blog, Injection Molding, Inventors

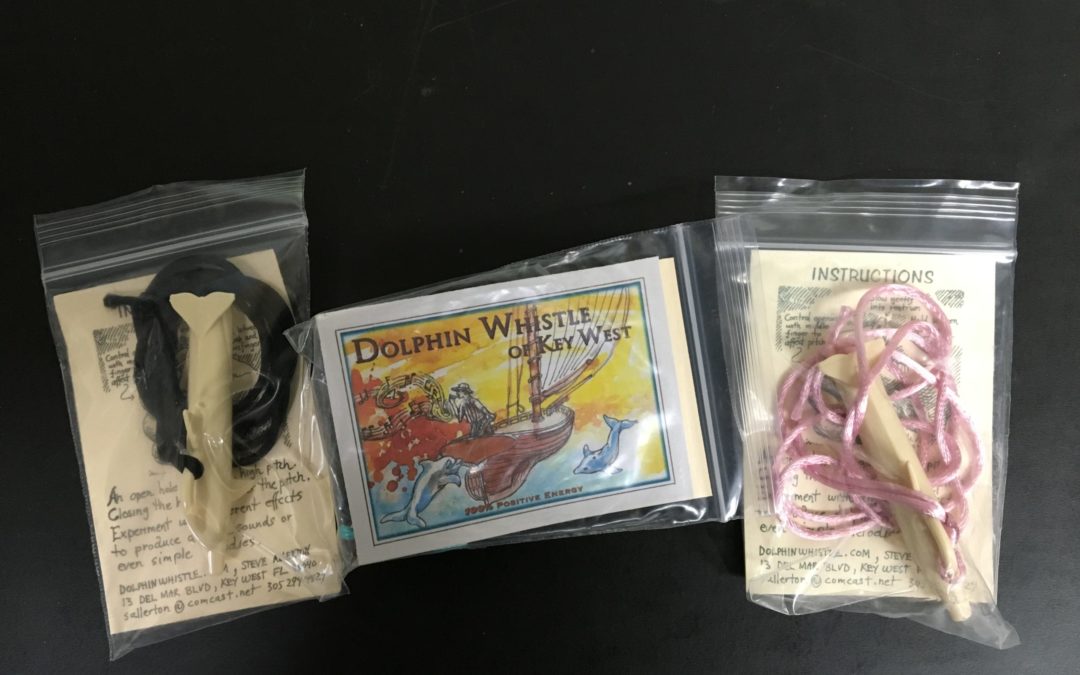

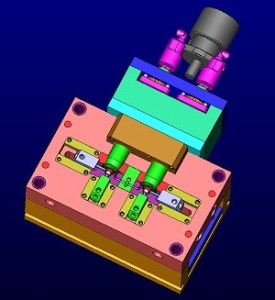

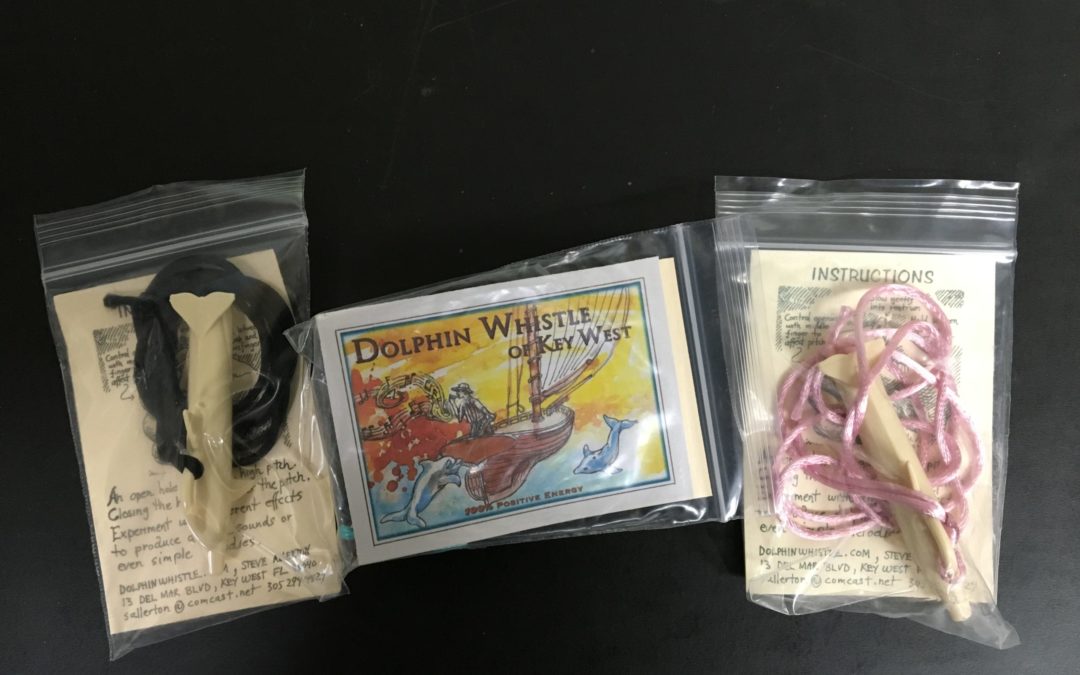

Developing plastic parts using the injection molding process first begins with a concept whether it is a new product or changing/re-designing an existing one. Second will be the design stage. Once these two steps are completed, often a 3-D printed part is made to test...

by Tim Toth | Sep 1, 2020 | Blog, Troubleshooting

One of the most common problems in injection molding is determining the shrinkage rate of a part that is going to be injection molded. Material data sheets provide a shrinkage rate for the material that is going to be used for a part. However, this rate is only a...

by Tim Toth | Jul 27, 2018 | Blog, Injection Molds

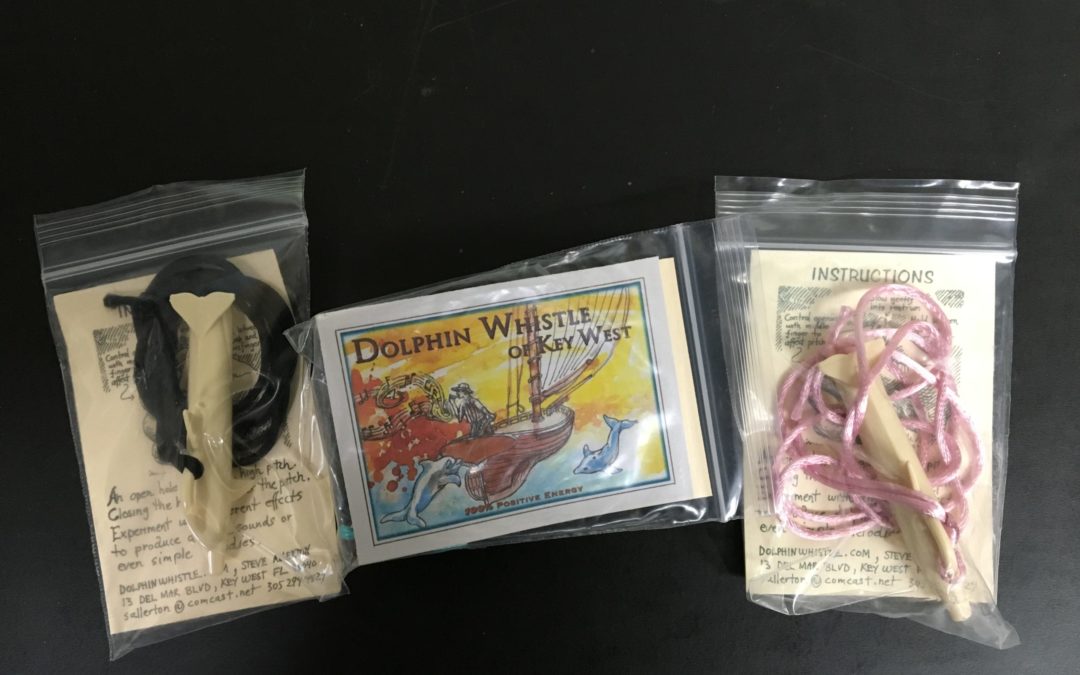

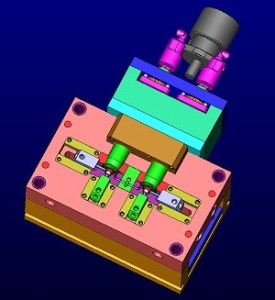

Injection Molding Process An injection mold used in the injection molding process, consists of a two piece mold that is opened and closed to allow plastic to be injected under tremendous pressure when the mold is closed, to create a part. After a short...

by Tim Toth | Feb 27, 2014 | Blog, Miscellaneous

I have been building molds and also injection molding for over 30 years. Technology keeps us moving forward. When I was learning the trade, it was a trade that I knew you had to be committed to. The time that was involved in learning all of the different steps from...

by Tim Toth | Feb 19, 2014 | Blog, Injection Molds

There is a large selection of different types of steel used for various applications in the manufacturing of all types of products. In the injection molding industry, there are common steels used for different parts of an injection mold. One of the driving...