I have been building molds and also injection molding for over 30 years. Technology keeps us moving forward.

When I was learning the trade, it was a trade that I knew you had to be committed to. The time that was involved in learning all of the different steps from mold design, mold build and then the injection molding process was very time consuming and took much dedication. Probably one of the biggest differences in the industry today is in the mold design process.

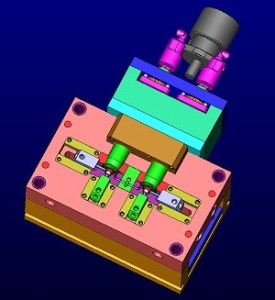

Years ago, there were only 2D drawings available in the injection molding industry that would give all the detail, dimensions and the geometry of the part. Today with computers and software 3D solid modeling just about does the mold design for you. You can rotate, cut and zoom in on any detail. There really is nowhere near the challenge of designing a mold as it was years ago. Most of the molds built today are done without 2D prints. The solid models of injection molds can be sent right to the CNC machines for programming and cutting of the cavities, cores and all mold components. Next, the moldmakers must then assemble the mold after all the machining is done.

However, to me this is an art. The mold assembly is all about the final fitting of all the components and is where problems show up if things start getting too tight or loose. Today, many of the moldmakers working on the mold do not even know what material is being molded. Without knowing this, the final fitting of the mold cannot be done properly. Some materials flash easier than others and must be fit taking that into account. Toth Mold/Die Inc. incorporates natural venting into their molds and this can only be done if the material that is being molded is known. With all of the new technology available in the injection molding industry today, there are virtually no limitations to the shape and contour of parts which is probably one of the biggest advantages.

Old Timer Injection Molding vs. “Technology” Injection Molding

There still are plenty of reasons that always pop up for cause to go back to the old technology of moldmaking and use the back to basics tricks of the trade that right now are known by the so called old timers. In short, to me, there is no satisfaction greater than still building a mold the so called manual way. In my opinion, injection molding and injection mold building will keep changing with new technology, but the demand for moldmakers with the old timer mentality and expertise will increase due to the shortage of old time moldmakers.