by Tim Toth | May 27, 2021 | Blog, Miscellaneous

I was showing molded parts to a customer from our display case and a particular project brought back many memories. This month, we proudly celebrate our 39th business anniversary. We started Toth Mold/Die Inc. in 1982 but we actually have 45 years in the injection...

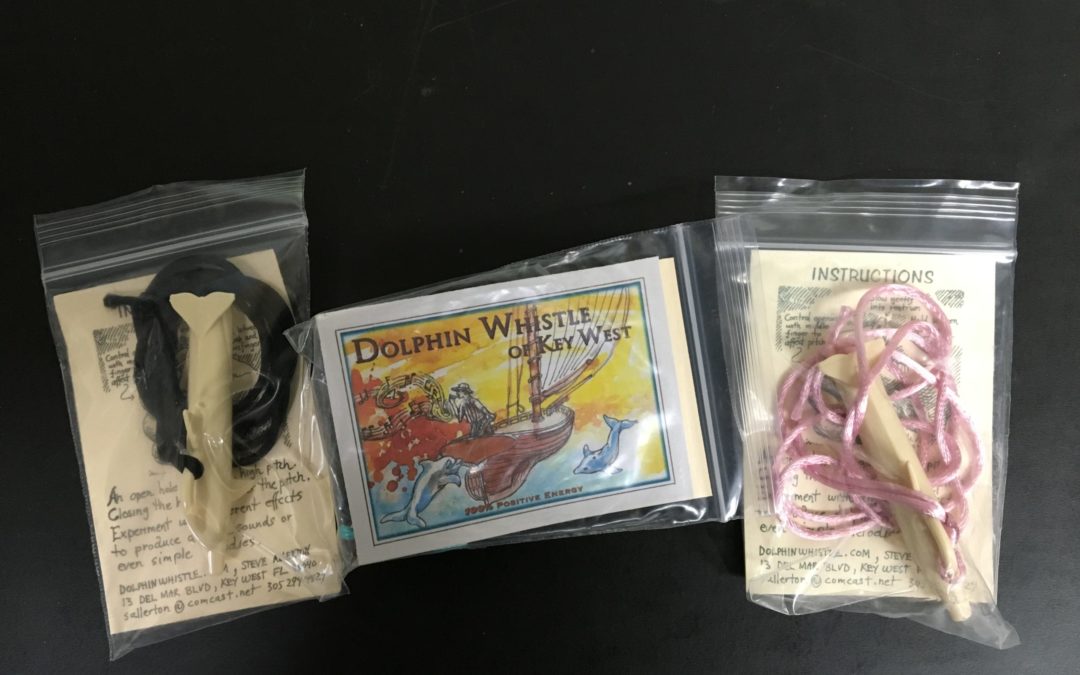

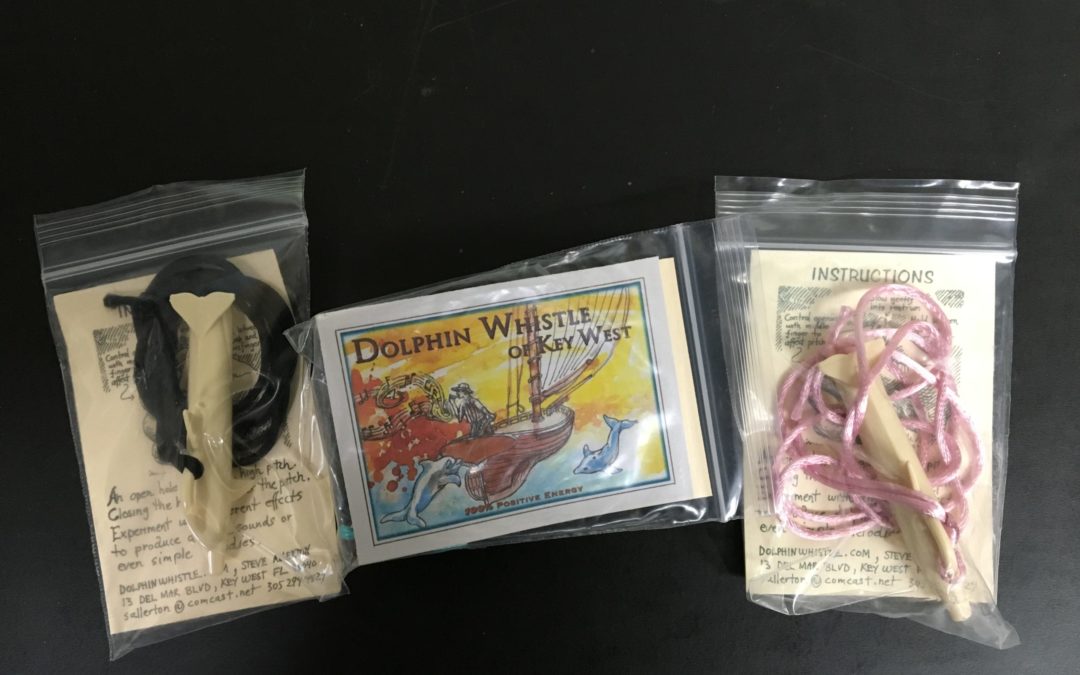

by Tim Toth | Mar 16, 2021 | Blog, Injection Molding, Inventors

Developing plastic parts using the injection molding process first begins with a concept whether it is a new product or changing/re-designing an existing one. Second will be the design stage. Once these two steps are completed, often a 3-D printed part is made to test...

by Tim Toth | Dec 1, 2020 | Blog, Injection Molding, Injection Molding Company

What is an Injection Molding One Stop Shop? An Injection Molding One Stop Shop is a company that provides all the services you need to produce a product from start to finish. There are companies out there that claim they are a One Stop Shop for injection molding but...

by Tim Toth | Oct 1, 2020 | Blog, Injection Molding

PPE – The Sudden Need for Personal Protective Equipment 2020 will go down in the record books for many things. Besides the ongoing fight to eradicate COVID-19, we’re hoping this year has opened our eyes, as Americans, to how vulnerable we are. Our free market...

by Tim Toth | Sep 1, 2020 | Blog, Troubleshooting

One of the most common problems in injection molding is determining the shrinkage rate of a part that is going to be injection molded. Material data sheets provide a shrinkage rate for the material that is going to be used for a part. However, this rate is only a...