What is an Injection Molding One Stop Shop?

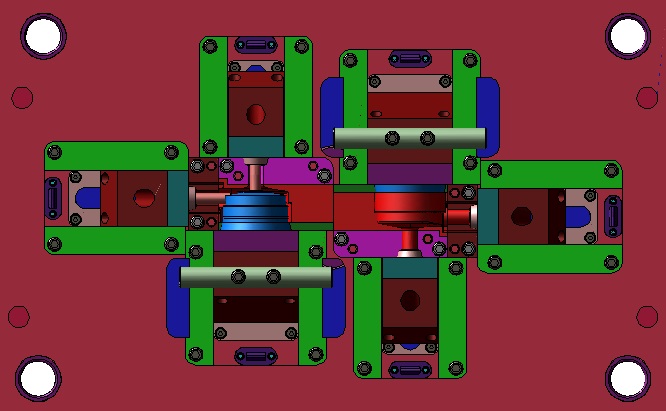

An Injection Molding One Stop Shop is a company that provides all the services you need to produce a product from start to finish. There are companies out there that claim they are a One Stop Shop for injection molding but some truly are not. These types of companies end up sourcing out the part design, mold build and production run. At Toth Mold/Die Inc. all of our services are done in-house. From the initial part design to the production of finished parts, we do it all. At Toth Mold/Die Inc., we have a 100% hands-on involvement with your part.

An Injection Molding One Stop Shop Saves Time and Money

Using an Injection Molding One Stop Shop eliminates a lot of wasted time and expense. Developing a product is not an easy task. At times, there may be many adjustments that are needed during the development process. For example, once the part design is finished and the mold is built, there are often issues with fits and functions of the product. A majority of the time, adjustments need to be made. At Toth Mold/Die Inc., we can make any necessary changes to the mold and have it back in the machine usually in the same day. Companies that are not a One Stop Shop will need to send the mold out to have adjustments made. This process can take up to two weeks or longer. It is important to keep in mind that this situation can happen more than once.

Avoid Improper Product Design

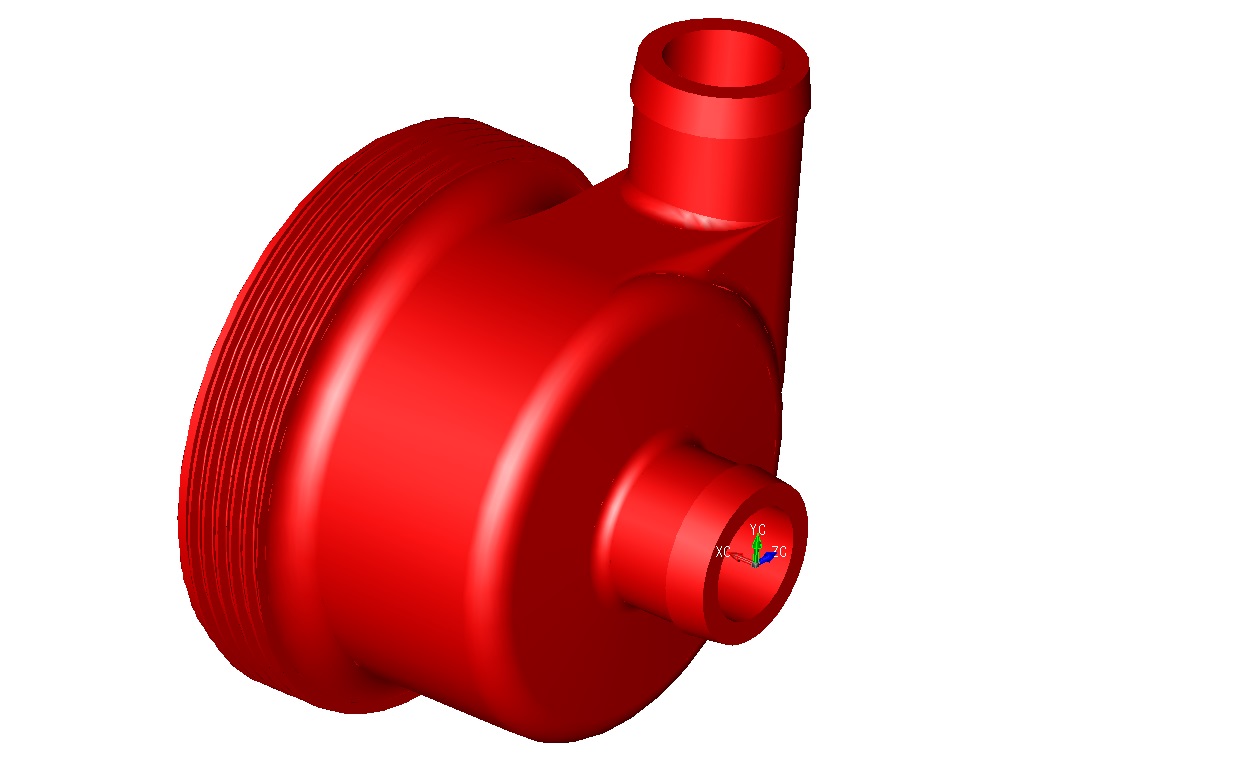

Another time-consuming component of producing your part is the part design itself. Some companies have to job their designing out to places that are not familiar with injection molding. Therefore, this can lead to a lot of design changes in order to make the part injection moldable. Sometimes there are features that cause the part to be almost impossible to injection mold or will require a costly expense added to the mold. However, these issues are completely bypassed at Toth Mold/Die Inc. The part design is done in-house and it is always taken into consideration that the part is being injection molded.

We have had numerous and potential customers inquire if their part can be injection molded after they were told by other injection molders that the part cannot be molded. At Toth Mold/Die Inc. we always have a way to do it since we do all aspects of the product design. Sometimes it is just a minor change that is needed or we figure out a way to mold it with our expertise and years of experience.

As an Injection Molding One Stop Shop for over 38 years, Toth Mold/Die Inc. offers comprehensive in-house services including part design, mold design, mold building, molding production, troubleshooting and consulting. Most importantly, the owners are 100% hands-on with all products from start to finish. If you have never used a One Stop Shop, give us a try. You will be glad you did!