INJECTION MOLDS

Toth Mold/Die Inc. Since 19821. Prototype Molds

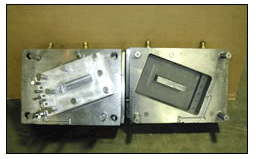

All types of prototype molds have a life expectancy of 100 parts up to 10,000 parts depending on the customer’s requirements. Some parts may be a candidate for use in one of Toth Mold/Die Inc.’s mold bases. We have an assortment of sizes available. The advantage to this, is that there is no cost to the customer for the use of the mold base. This helps reduce the total price for producing the prototype mold. The customer is only charged for the cavity and core inserts. Toth Mold/Die Inc. also uses a variety of hand loaded inserts to cast holes, undercuts and other features that would otherwise require cam action slides. Additionally, Toth Mold/Die Inc. uses hand loaded cores to cast internal threads without the use of unscrewing motors.

All types of prototype molds have a life expectancy of 100 parts up to 10,000 parts depending on the customer’s requirements. Some parts may be a candidate for use in one of Toth Mold/Die Inc.’s mold bases. We have an assortment of sizes available. The advantage to this, is that there is no cost to the customer for the use of the mold base. This helps reduce the total price for producing the prototype mold. The customer is only charged for the cavity and core inserts. Toth Mold/Die Inc. also uses a variety of hand loaded inserts to cast holes, undercuts and other features that would otherwise require cam action slides. Additionally, Toth Mold/Die Inc. uses hand loaded cores to cast internal threads without the use of unscrewing motors.

One of the most important items when building a prototype mold is not only to produce functional parts, but also to be able to visualize a finished part’s cosmetics as far as warpage, shrink and surface finish. All of these factors are usually dictated by mold cooling, gate location and venting. At Toth Mold/Die Inc., all of these important features are built into the prototype mold the same as if it is a production mold.

Having a prototype injection mold made is a very important step in producing your injection molded part. Here are a few guidelines that will help make the process as simple as possible. At this stage, you should already have a part design complete which was most likely prepared by a designing firm. This is the expensive way to start out because of the high cost these firms must charge since that is the only service they offer. The most cost effective way is to find a shop that can provide this service along with building the prototype injection mold as well. At Toth Mold/Die Inc. we provide the service of designing a part even if the customer just has a concept in mind. The biggest advantage of this is we can design the part to make it as easy as possible to injection mold. Design shops most likely do not have the experience in injection molding and therefore, can design a part that functions well, but is impossible to injection mold.

More About Prototype Molds

A few items must be addressed before you give a purchase order and a down payment on your prototype mold. You will need to find out vital information pertaining to the prototype mold such as:

- How many parts is the prototype able to produce?

- Who owns the mold?

- Are there any engineering changes included in the price?

Toth Mold/Die Inc. can guide you in this important step to get you started in producing your new product.