INJECTION MOLDING

Toth Mold/Die Inc. Since 1982Short Run and Hand Load

Do you have a low volume production part?

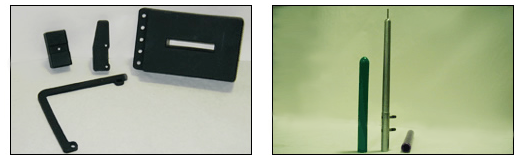

Injection molding is used for high volume production. Injection molds can be very expensive which makes it cost prohibitive for low volume production. Most of the time, another process needs to be used to produce the part(s) to keep the initial cost down. However, sometimes there is no other option than injection molding. When this situation occurs, Toth Mold/Die Inc. has different mold options to keep the initial mold cost down.

When parts need to have internal threads cast, it could cost thousands of dollars to produce because the use of hydraulics, motors or collapsible cores are needed. Toth Mold/Die Inc. can supply hand loaded inserts that would need to be unscrewed manually to reduce the cost by at least 20%. Hand loaded inserts are also used to replace cam action slides. Toth Mold/Die Inc. also is able to use one of their mold bases which means the customer is only charged for the cavity inserts.

Short Run and Hand Load Video